fused-polyhedra in additive manufacturing

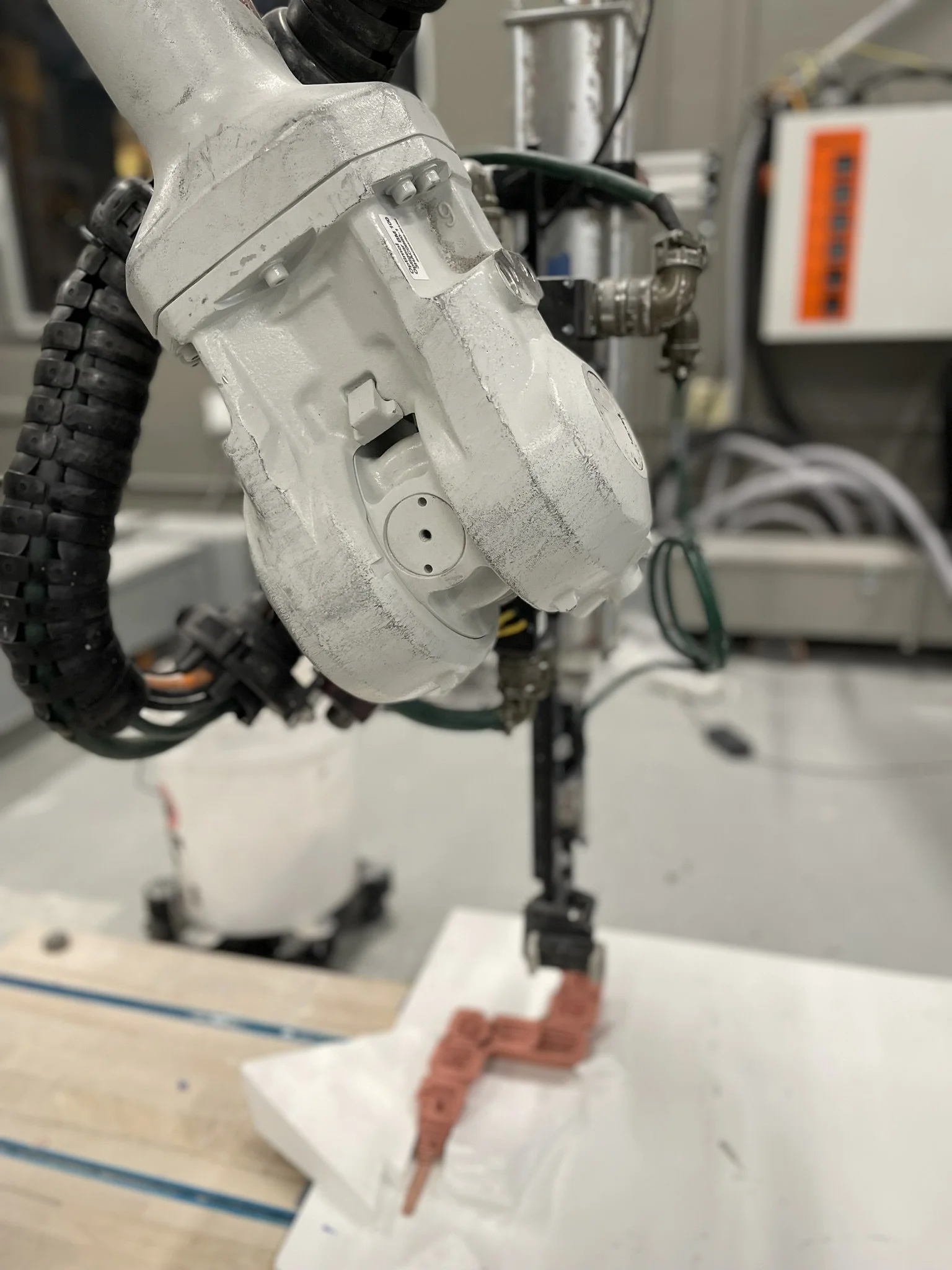

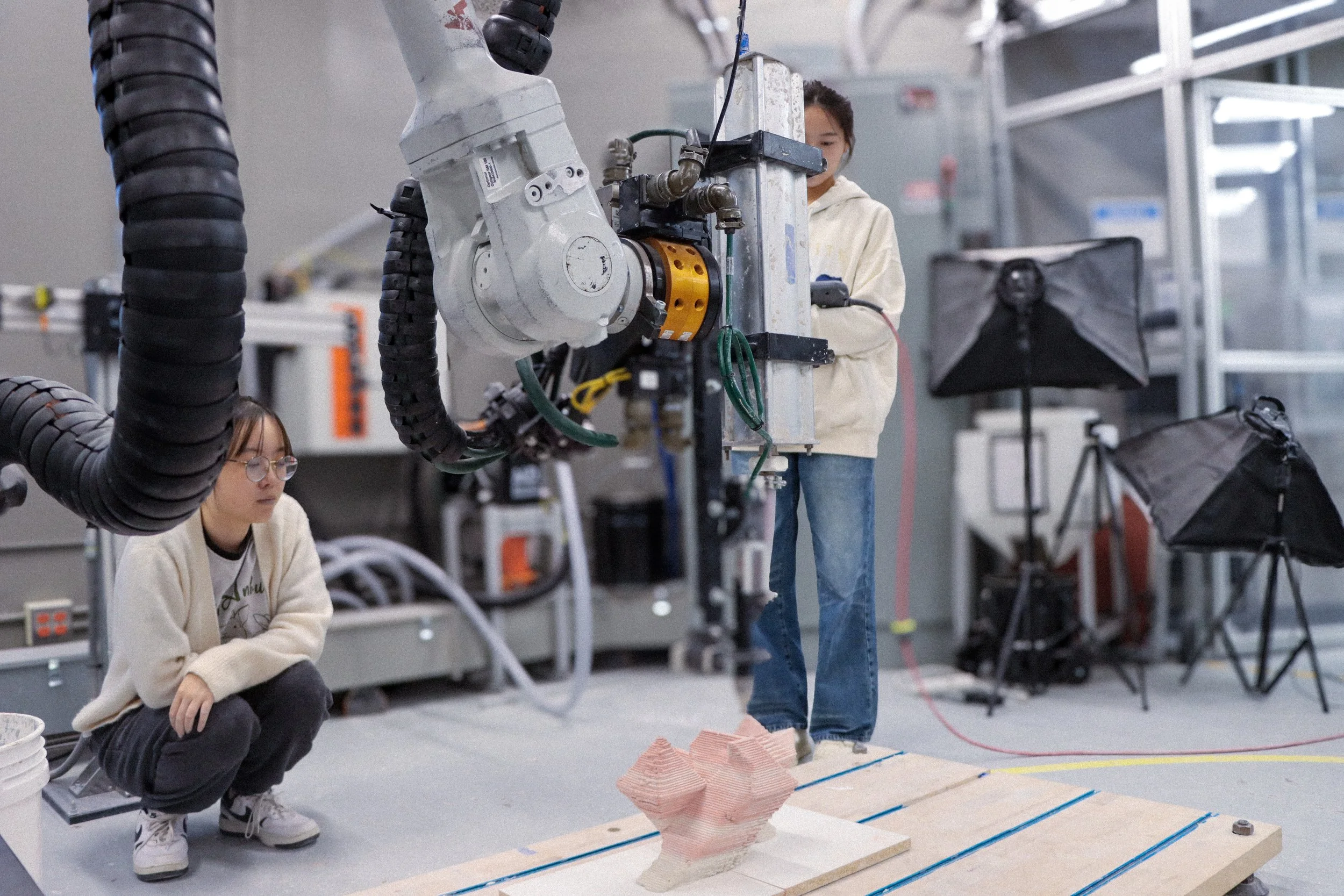

Computationally-Driven Robotic Clay Deposition for Bespoke Interlocking Structures

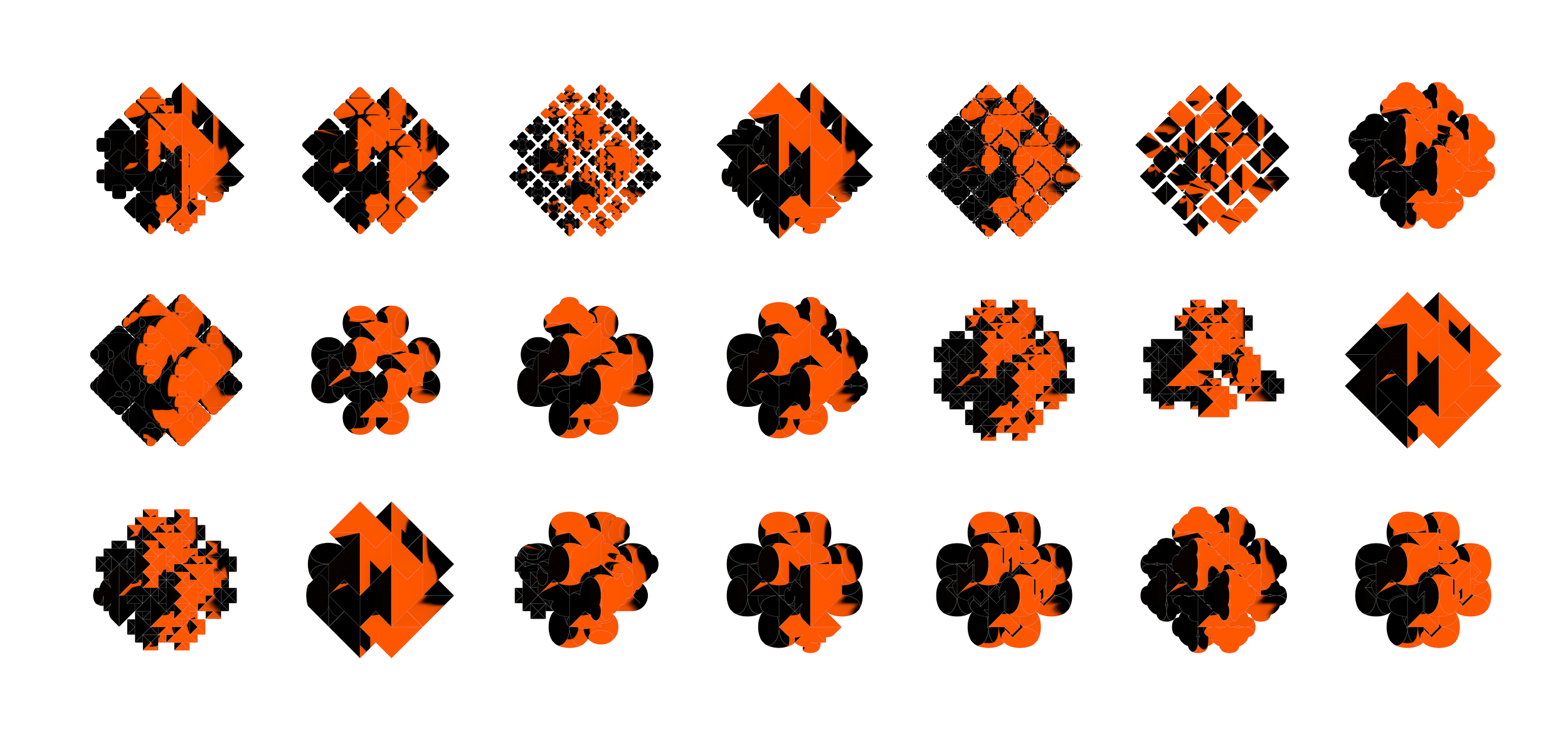

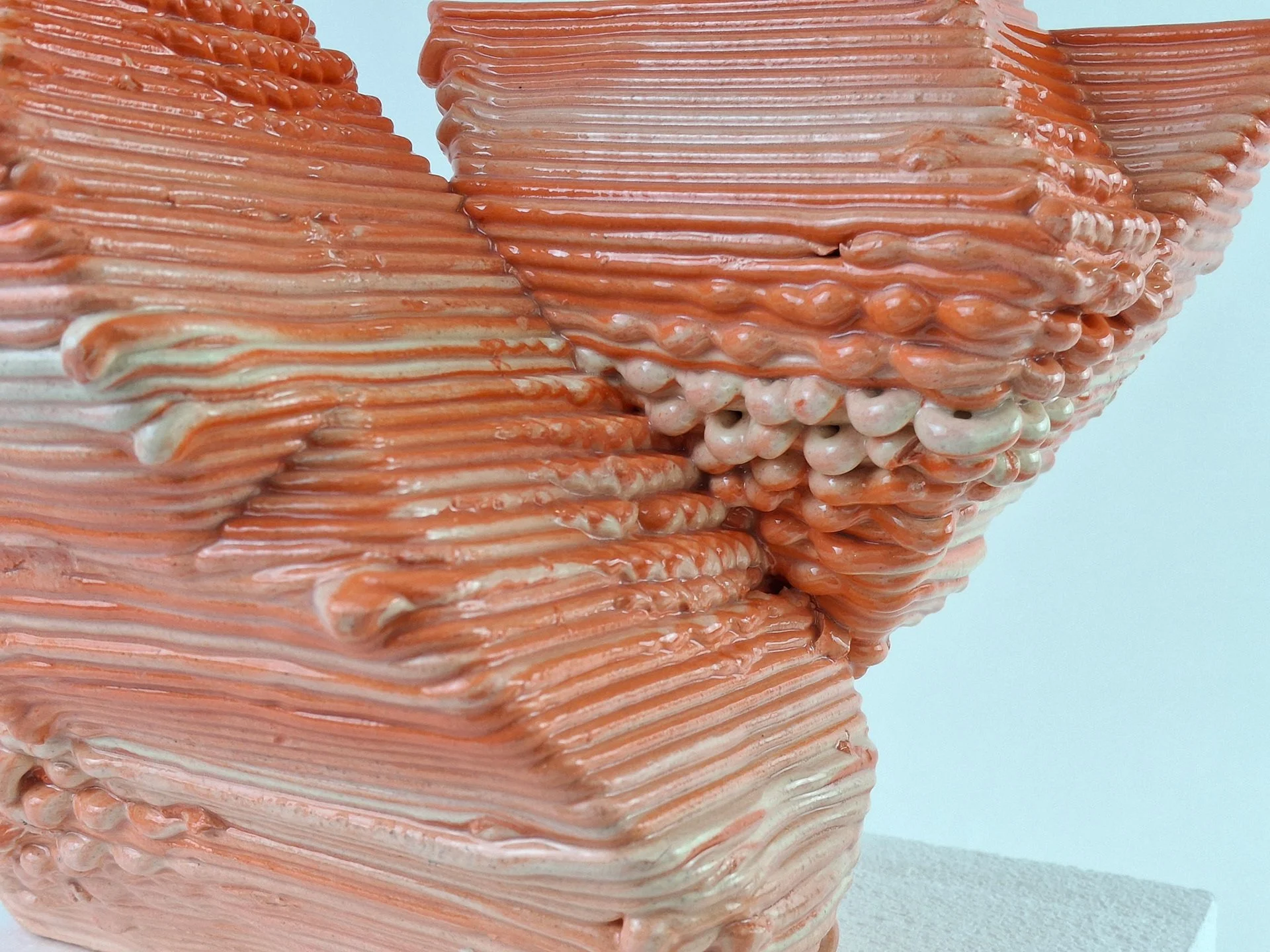

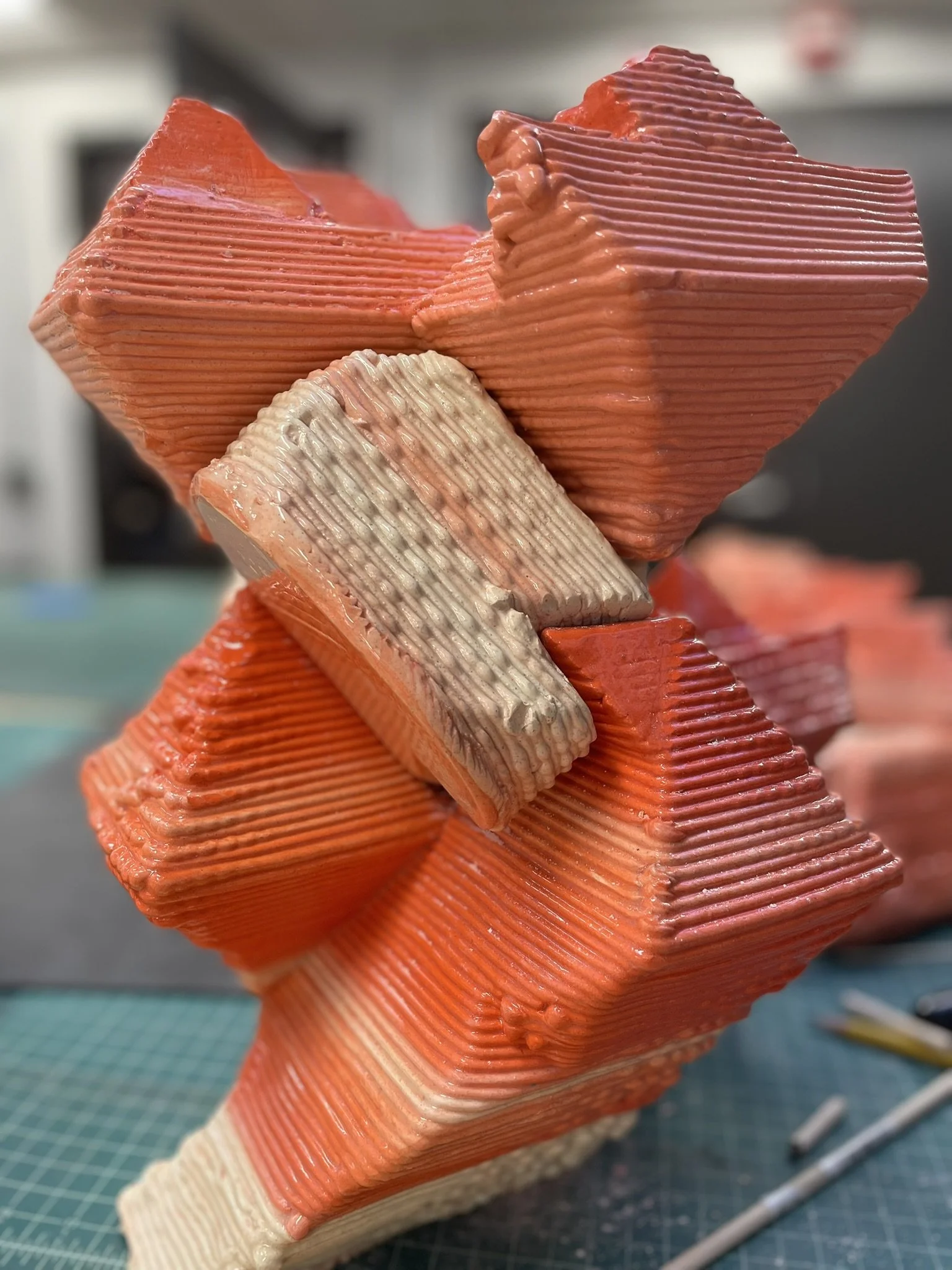

The project investigates the fusion of geometric principles with advanced robotic fabrication techniques, drawing inspiration from Robinson Fredenthal’s sculptural work. At its core, the research explores the spatial relationships between octahedrons and tetrahedrons, leveraging their inherent space-filling properties to generate fused polyhedra. Through computational algorithms, octahedrons are iteratively fitted within tetrahedrons, varying in scale and orientation to create bespoke interlocking structures. Boolean operations introduce curvature, transforming rigid polyhedral forms into fluid, continuous geometries that enhance both structural integrity and scalability.

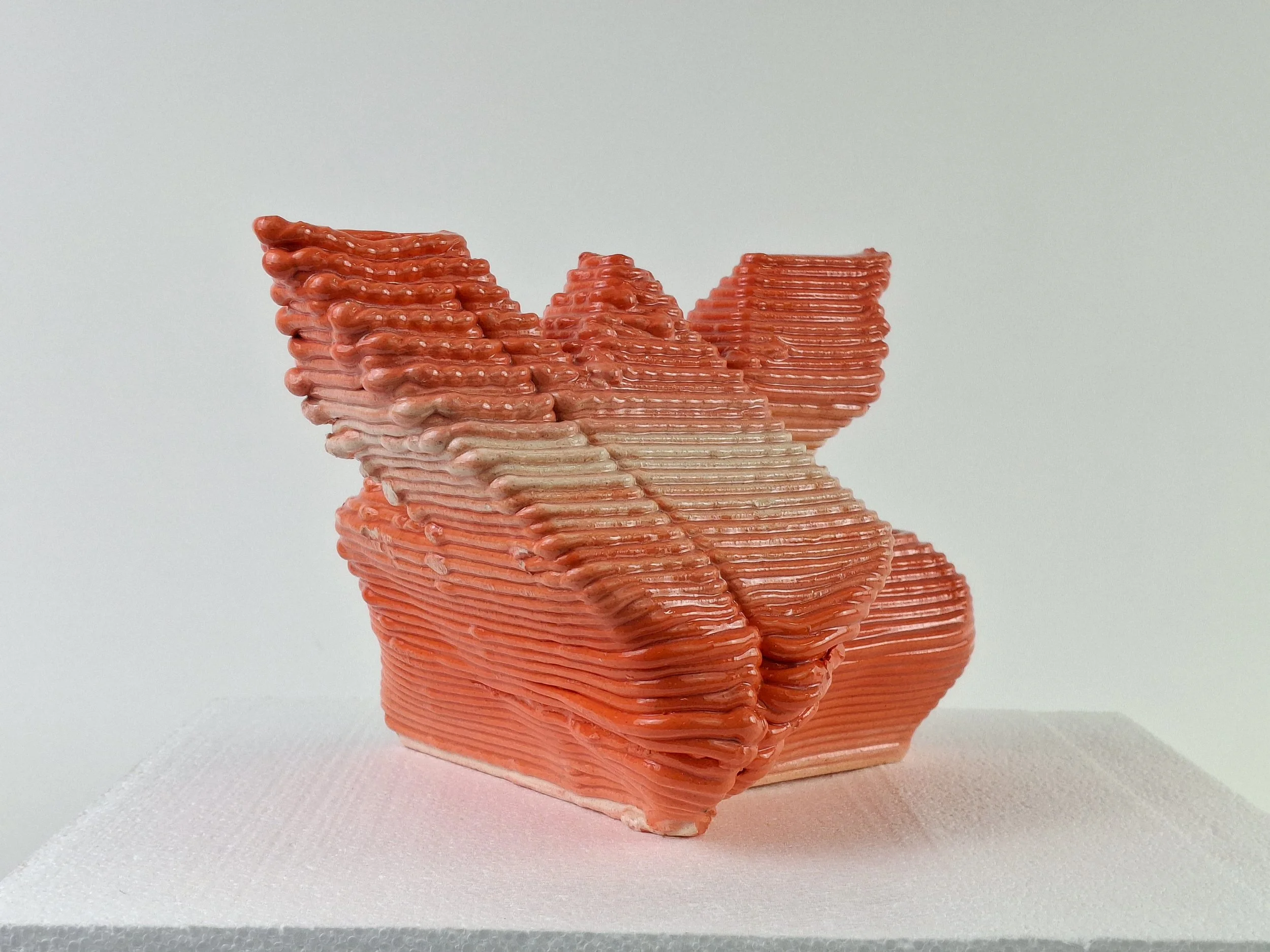

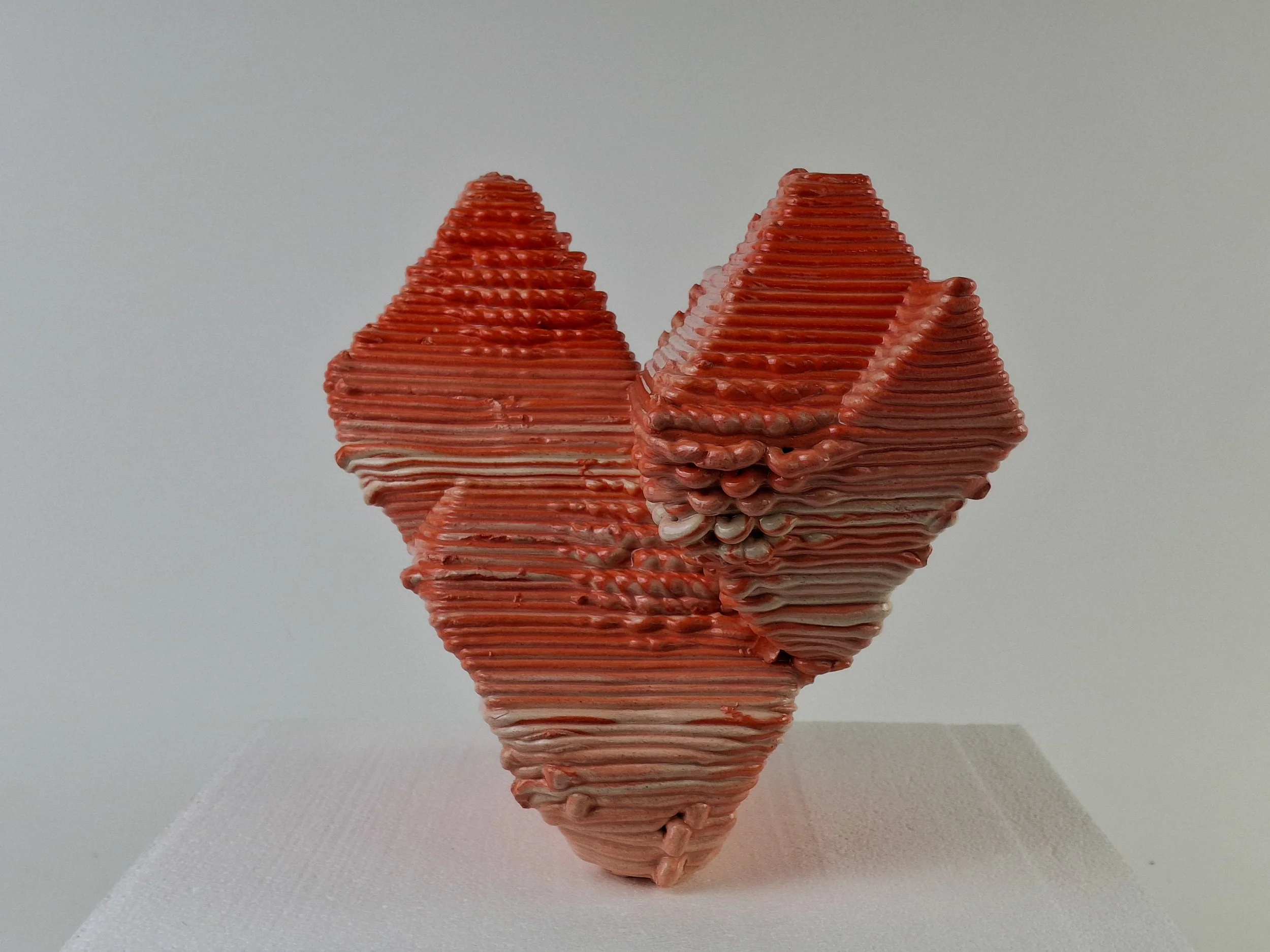

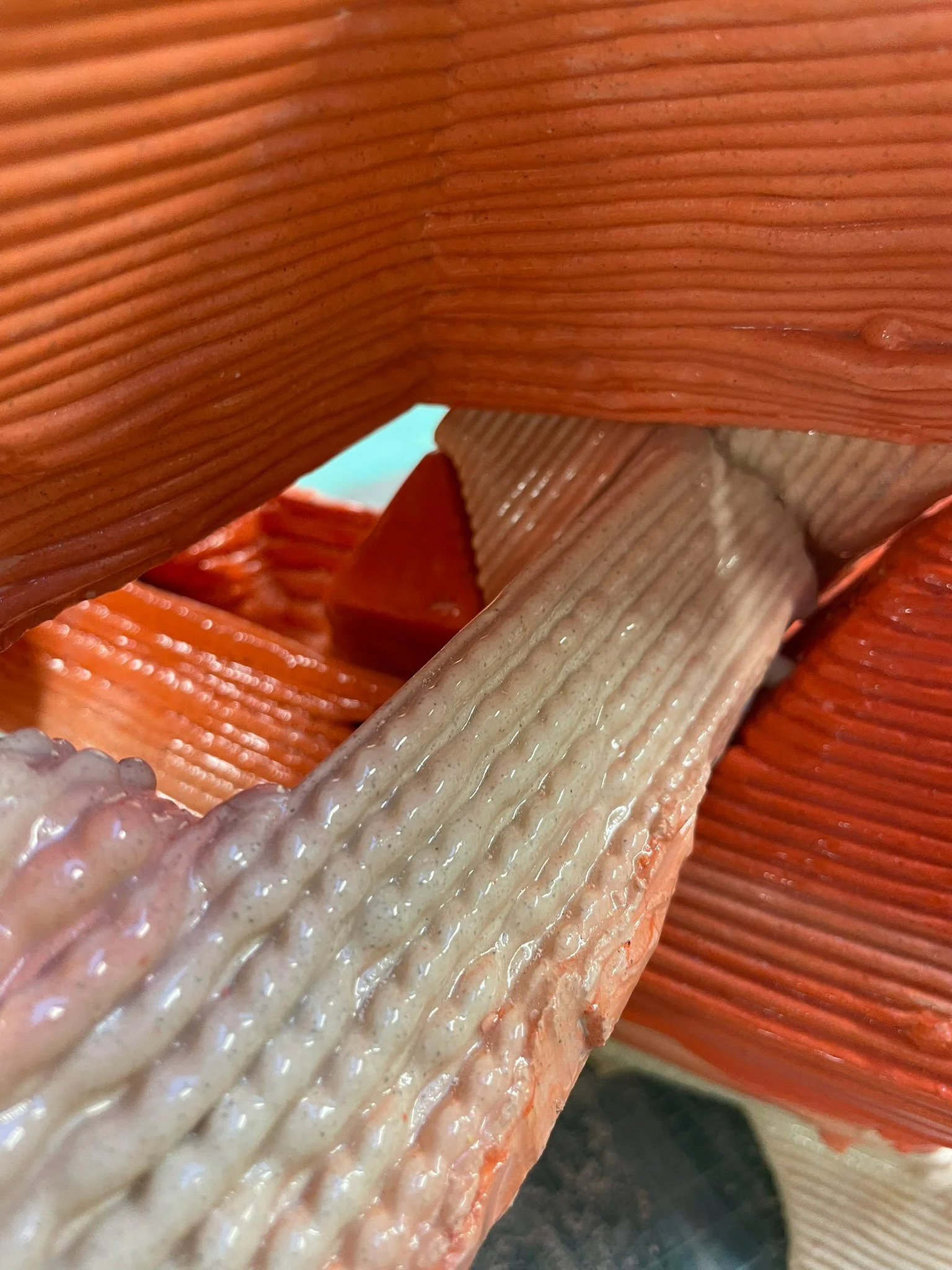

Beyond geometry, the project also explores material innovation by incorporating pigment into the clay mix. Various layering methods are tested to achieve controlled gradient patterns during robotic deposition. One approach involves stacking layers of differently pigmented clay to create precise, gradual color transitions, while another method places pigments vertically, resulting in unpredictable and organic blending. These strategies balance randomness with control, offering new opportunities for both aesthetic expression and material performance in additive manufacturing.

Fabrication challenges arise from the unpredictability of clay behavior during deposition. To address this, an algorithm optimizes the orientation of each component, preventing print failures due to cantilevers and ensuring structural stability. By integrating computational design with robotic clay deposition, the project pushes the boundaries of additive manufacturing, demonstrating how fused polyhedra and pigment-layering techniques can redefine material expression and geometric interlocking in architectural and sculptural applications.

Institution: University of Pennsylvania

Lab: Advanced Research and Innovation lab

Instructor: Andrew Saunders

Co-Instructors: Claudia Campuzano, Nick Houser

Lab Managers: Nicholas Sideropoulos, Shunta Moriuchi

In Collaboration with: Kristyna Wang, Freda Odonye, Lucy Rong.

Generative Model Workflow: From Subdivision to Interlocking Systems

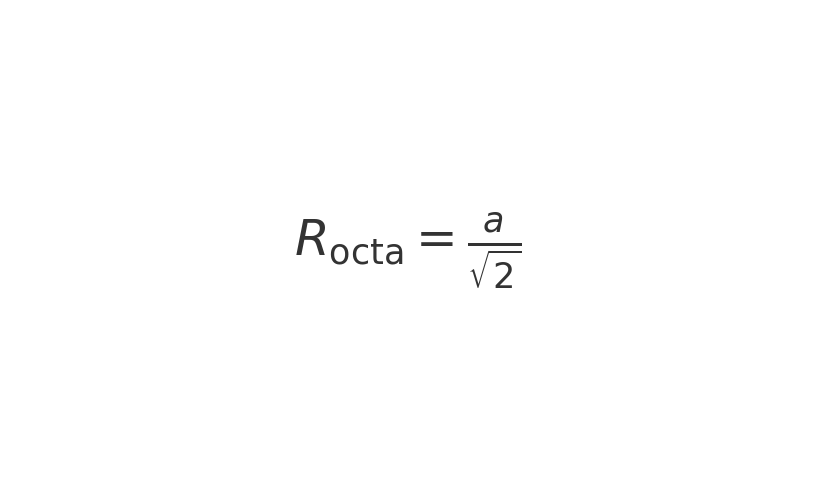

The generative process begins with an algorithm that iteratively subdivides a tetrahedron by embedding octahedrons within it, maintaining a structured yet adaptable geometric system. The relationship between the octahedron and tetrahedron is governed by the formula, where R octa represents the radius of the inscribed octahedron, and a is the edge length of the tetrahedron. This formula ensures precise scaling, allowing for controlled geometric subdivision.

iteratively subdivides a tetrahedron by embedding OCTAHEDRA

The relationship between the octahedron and tetrahedron is governed by the formula, where R octa represents the radius of the inscribed octahedron, and a is the edge length of the tetrahedron.

Define Spheres from the tetrahedra

Spheres are generated to either fit within the octahedron or touch all the corners of a tetrahedron. These spheres are then boolean-subtracted from the polyhedral framework, introducing curvature and breaking the rigidity of the original geometry. The workflow transitions into an interlocking system, where an auto-selection algorithm alternates adjacent tetrahedrons relative to their corresponding octahedrons, forming intricate, self-supporting connections. This approach enables a scalable and modular assembly, bridging computational geometry with robotic additive manufacturing.

interlocking

In addition, the interlocking system we developed transforms these fused polyhedra into a scalable, puzzle-like structure. Each unique part interlocks with the next due to the geometric precision of the fused forms, generating intriguing seams that further enrich the visual and spatial experience. Structurally, this method increases the stability and load distribution within the form, making the assembly process more efficient and scalable for larger architectural or sculptural applications.

3d printing orientation optimization

One of the key challenges we faced was the unpredictability of clay during the fabrication process. Unlike Fredenthal’s metal sculptures, working with a malleable material like clay required a careful balance between form and structural integrity. To overcome this, we developed an additional algorithm that optimally oriented each part of the structure, preventing common printing issues such as cantilevers or material sagging. This solution significantly improved the success rate of our prints and allowed us to maintain the geometric precision needed for seamless assembly.